Understanding the Engine Fuel Injection System: A Comprehensive Guide for Vehicle Efficiency. Discover how The engine fuel injection system works in our easy guide. Boost your vehicle’s efficiency & performance with simple tips & insights!

What is Understanding The Engine Fuel Injection System: A Comprehensive Guide for Vehicle Efficiency & how does it work?

Engine fuel injection system delivers precise fuel amounts. This system optimizes combustion for better performance. Sensors detect engine conditions constantly. Data helps adjust fuel mixture dynamically. Modern designs enhance overall vehicle efficiency significantly.

Brief history of Understanding The Engine Fuel Injection System: A Comprehensive Guide for Vehicle Efficiency

Fuel systems evolved alongside automotive technology. Early engines used carburetors for fuel delivery. In 1950s, electronic fuel injection emerged. This breakthrough allowed for better control & efficiency. By 1980s, fuel injection became standard in many vehicles.

How To implement Understanding The Engine Fuel Injection System: A Comprehensive Guide for Vehicle Efficiency effectively

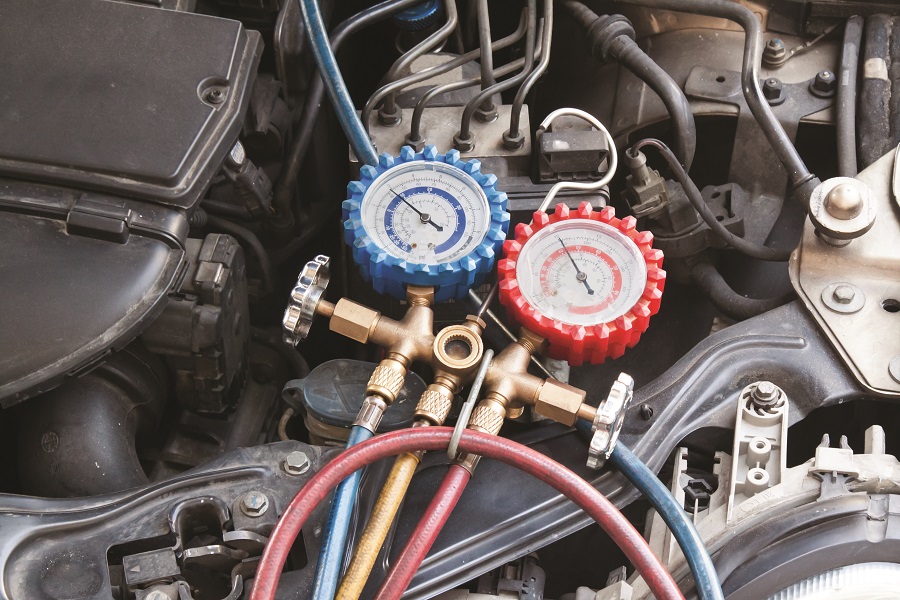

Installation requires specific tools & training. Begin by removing old components carefully. Installer needs proper settings for new parts. Use manufacturer guidelines for adjustments. Testing ensures all systems function as intended.

Key benefits of using Understanding The Engine Fuel Injection System: A Comprehensive Guide for Vehicle Efficiency

- Improved fuel economy for longer distances.

- Enhanced power output during acceleration.

- Lower emissions contributing To environmental health.

- Better engine response during varying conditions.

- Reduced maintenance costs over time.

Challenges with Understanding The Engine Fuel Injection System: A Comprehensive Guide for Vehicle Efficiency & potential solutions

Systems may experience compatibility issues with older engines. Upgrading can require additional modifications. Regular maintenance prevents problems before they escalate. Consulting professionals ensures all components work harmoniously. Keeping software updated also combats potential glitches.

Future of Understanding The Engine Fuel Injection System: A Comprehensive Guide for Vehicle Efficiency

Innovation will drive fuel injection technologies forward. Advanced systems promise integration with hybrid models. Autonomous vehicles will utilize smart fuel delivery mechanisms. Researchers explore alternative fuels for better sustainability. Expect enhancements in accuracy & efficiency over time.

Table of Understanding The Engine Fuel Injection System: A Comprehensive Guide for Vehicle Efficiency

| Aspect | Description |

|---|---|

| Type | Electronic Fuel Injection |

| Benefit | Increased efficiency & performance |

| Challenge | Compatibility issues with older models |

| Future Trend | Integration with electric & hybrid vehicles |

Understanding Engine Fuel Injection Systems

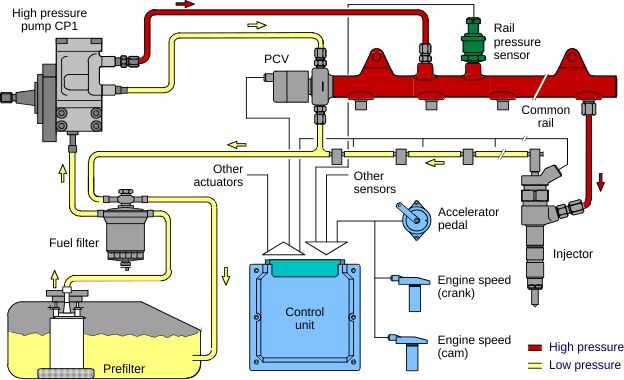

Fuel injection systems play a vital role in engine performance. They enhance vehicle efficiency significantly. A clear understanding of these systems helps in optimal vehicle operation. Fuel injection involves delivering precise amounts of fuel into combustion chambers. This process differs from older carburetor systems. Modern vehicles employ electronic fuel injection (EFI) for greater efficiency. For more information, refer To this source.

Types of Fuel Injection Systems

Electronic Fuel Injection (EFI)

EFI uses electronic controls for better fuel delivery. These systems include sensors that monitor engine conditions. They adjust fuel flow based on engine demands. This adaptability enhances performance & efficiency, minimizing emissions. Various parts, such as fuel injectors & control modules, work together seamlessly.

EFI systems offer multiple benefits. They enable improved fuel atomization, ensuring complete combustion. This results in more power with less fuel. Moreover, adjustments occur almost instantaneously, making engines more responsive. Drivers experience smoother acceleration & power delivery.

Another advantage involves diagnostic capabilities. EFI systems can detect issues proactively, providing error codes. These codes help mechanics identify problems quickly, saving time & costs. Routine maintenance becomes simpler with standardized diagnostics for EFI systems.

Port Fuel Injection (PFI)

PFI systems inject fuel directly into intake manifolds. This method allows fuel To mix with air before entering The combustion chamber. Consequently, PFI systems promote even fuel distribution. This distribution leads To improved overall engine performance.

Operations under various conditions benefit significantly from PFI. Fuel injected at low speeds enhances drivability. At high RPMs, it maintains power output efficiently. Advanced versions of PFI offer features such as dual-stage injection.

One limitation of PFI systems involves carbon buildup. Over time, deposits may form on intake valves. Regular maintenance routines should include cleaning these components. Enhancing airflow into The combustion chamber contributes To ongoing performance.

Direct Fuel Injection (DFI)

DFI systems differ by injecting fuel directly into combustion chambers. This process occurs under high pressures, allowing precise control over fuel delivery. Such systems boost engine efficiency, yielding higher power levels from smaller engines.

Another significant benefit comes from reduced emissions. DFI systems employ stratified charge combustion. This technique minimizes unburned fuel within exhaust systems. Consequently, DFI improves vehicle performance without negatively impacting fuel economy.

However, DFI engines require regular maintenance due To potential issues. Carbon buildup can affect performance if not managed. Drivers should schedule cleanings To maintain optimal efficiency. DFI systems symbolize cutting-edge technology in fuel management.

Key Components of Fuel Injection Systems

Fuel Injectors

Fuel injectors serve as crucial components of these systems. Their primary function entails atomizing fuel for easier combustion. Proper atomization ensures that fuel mixes evenly with air. Thus, effective combustion can occur within cylinders.

Maintaining fuel injectors involves several procedures. Regular cleaning prevents clogging, which impacts performance. Additionally, replacing damaged injectors is vital for continued efficiency. Mechanic inspections regularly identify any injectors needing replacement.

In recent developments, advanced fuel injectors have emerged. These injectors offer more precise control. Features such as multiple spray patterns enhance performance across various conditions. Ultimately, investing in high-quality injectors proves beneficial.

Fuel Pumps

Fuel pumps supply fuel from storage tanks. They create pressure, allowing fuel flow towards injectors. Proper fuel pressure must be maintained for efficient operation. Insufficient pressure may result in poor engine performance.

Different types of fuel pumps exist, including mechanical & electric variations. Electric fuel pumps offer heightened efficiency & reliability. They operate quietly, enhancing overall driving experiences. Regular checks on fuel pump performance ensure optimal function.

Signs of failing fuel pumps can vary. Symptoms include sputtering, hesitation, or engine stalling. Detecting these signs early allows for timely replacements. Routine maintenance plays a key role in sustaining fuel pump efficiency.

Fuel Filters

Fuel filters protect The engine from impurities. These components ensure only clean fuel enters injectors & combustion chambers. Regularly replacing filters enhances performance by preventing clogs.

Various factors influence filter lifespan, such as fuel quality & driving habits. Dirty fuels hasten filter saturation, leading To blocked fuel flow. Maintaining clean fuel sources contributes significantly To filter efficiency.

Integrating a good quality fuel filter proves beneficial. A high-performing filter removes contaminants effectively. Ultimately, investing time into filter maintenance enhances overall vehicle efficiency.

How Fuel Injection Affects Vehicle Efficiency

Optimized Combustion Process

The injection system directly influences combustion processes. Properly atomized fuel allows for more efficient burning. Enhanced combustion leads To increased engine power & torque. This optimization results in greater fuel efficiency overall.

Additionally, fuel injection systems contribute towards regulating air-fuel ratios. Maintaining ideal ratios enhances combustion efficiency, reducing emissions. Consequently, engines become more eco-friendly, aligning with modern environmental standards.

Evaluating engine performance becomes easier thanks To these systems. Drivers can monitor efficiency through advanced onboard diagnostics. These systems provide real-time feedback To gauge how performance varies based on different conditions.

Reduced Fuel Consumption

Fuel injection systems lead towards remarkable reductions in fuel consumption. Efficient fuel delivery minimizes waste, allowing drivers more mileage. Achieving high fuel economy translates into lower operational costs.

Properly calibrated fuel injection systems optimize performance. Any deviations from optimal settings can lead towards inefficiency. Regular checks ensure injectors remain in prime condition, significantly affecting consumption rates.

Upon experiencing increased fuel efficiency, satisfaction follows. Drivers often report enjoying extended travel distances between fill-ups. This tangible benefit mirrors advancements in automotive engineering.

Enhanced Power Output

A well-functioning fuel injection system contributes towards higher power outputs. Precise fuel delivery equates To better acceleration & responsiveness. Turbocharged engines often benefit immensely from these improvements.

As performance expectations continuously rise, manufacturers implement advanced systems. Integration of dual or multi-port fuel injection techniques maximizes power across various RPM ranges. This overlap results in a calibrated & responsive drive.

Moreover, consumer preferences have shifted towards powerful yet efficient vehicles. Manufacturers strive To meet these demands by improving fuel injection technology. A clear correlation exists between these advancements & overall driver satisfaction.

Advantages of Fuel Injection Systems

Improved Emissions Control

Fuel injection systems excel at emissions reduction. Modern technologies allow for better combustion management. Enhanced atomization means fewer particulates escape into The atmosphere. This quality aligns with stricter environmental regulations.

Monitoring systems can fine-tune fuel delivery based on driving conditions. Responsive adjustments contribute To emissions reductions. In many cases, running engines at optimal mixtures leads towards reductions in harmful outputs.

Incorporating these innovations creates a cleaner driving experience. Eco-conscious consumers prioritize low-emission vehicles. Manufacturers recognize this market demand, spurring continued research & development in fuel technology.

Better Cold Start Performance

Fuel injection systems excel during cold starts. They provide necessary fuel under lower temperatures, enhancing reliability. Improved cold starting capabilities eliminate concerns for drivers in colder climates.

Specialized fuel delivery processes ensure proper engine startup, regardless of conditions. EFI systems incorporate algorithms To manage fuel supply precisely. Such enhancements build driver confidence, reassuring them regarding vehicle performance.

As automotive technologies advance, cold start systems improve concurrently. Enhanced control systems have emerged, creating a seamless cold-starting experience. Satisfaction stems from knowing vehicles will perform regardless of temperature conditions.

Increased Power & Torque

One prominent benefit of fuel injection systems involves higher power output. As fuel delivery & atomization improve, resulting torque increases substantially. Drivers enjoy exhilarating acceleration & smoother operation during various situations.

Recent innovations like turbocharging & supercharging have gained prominence. These technologies often use advanced injection systems. Such integrations elevate power delivery while ensuring optimal efficiency.

Consumers today seek vehicles that offer impressive power without compromising efficiency. As a result, manufacturers enhance their offerings. Meeting these expectations relies heavily on advancements in fuel injection systems.

Challenges in Fuel Injection Systems

Maintenance Requirements

While fuel injection systems provide numerous benefits, they require diligent maintenance. Regular inspections will ensure components remain in optimal condition. Clogged injectors negatively impact performance & efficiency.

Routine cleaning processes become crucial. Identifying signs of wear or malfunctions early can prevent costly repairs. Consistent maintenance ensures that vehicles operate as intended.

Moreover, drivers should track fuel quality consistently. Using poor-quality fuels increases contamination risks. Ensuring proper fuel quality mitigates detrimental effects on The injection system.

Dependence on Electronics

With advancements in technology, many fuel injection systems rely heavily on electronics. Such dependence introduces vulnerabilities, including electrical faults. Troubleshooting electronic issues requires specialized knowledge & tools.

Moreover, software updates & calibrations require regular attention. Integrating & refining electronic controls influences overall functionality. Consumers should consider these factors when selecting a vehicle.

Despite challenges, electronic fuel injection leads towards considerable benefits. These systems modernize vehicle capabilities while enhancing efficiency. Regular software updates contribute To longer-lasting systems.

Potential for Carbon Buildup

Carbon buildup represents a common challenge for fuel injection systems. Deposits can accumulate on injectors & intake valves over time. Significant buildups hinder performance, causing inefficiencies in The fuel delivery process.

Preventive measures exist. Regularly scheduled cleanings help reduce buildup over time. Additionally, utilizing high-quality fuels with fewer impurities extends injector lifespan.

Incorporating periodic inspections into maintenance routines helps identify buildup risks early. Addressing these concerns quickly minimizes potential performance drops. Drivers should commit towards keeping their fuel injection systems healthy.

Future Innovations in Fuel Injection Systems

Technological Advancements

Future developments in fuel injection systems promise enhanced performance & reduced emissions. Researchers continue exploring alternate fuel sources. Hydrogen, electricity, & biofuels show great potential for future applications.

Moreover, advancements in artificial intelligence will influence fuel management systems. AI technologies aim To create smarter engines overall, optimizing performance significantly. Data-driven adjustments will facilitate real-time adaptations.

Another emerging development includes direct injectors working alongside port injectors. Combining both methods maximizes fuel delivery efficiency across various conditions. Engineers seek improvements that continue meeting consumer expectations.

Hybrid & Electric Applications

Expanding hybrid & electric vehicle markets present new challenges. Alternative power sources necessitate advanced fueling technologies. Innovative fuel management systems will need adaptation for diverse vehicle architectures.

Electric vehicles will likely employ advanced algorithms for optimizing power consumption. Hybrid models will continue integrating fuel injection systems with electric motors. This combination maximizes fuel economy while ensuring reliable performance.

Furthermore, as electric vehicle technology progresses, hybrids will likely leverage advanced fuel injection systems To improve efficiency. Prioritizing these advancements leads towards greener automotive solutions.

Integration with Autonomous Vehicles

As autonomous vehicles approach reality, The integration of fuel systems becomes crucial. Enhanced advancements in sensor technologies will allow for more efficient fuel delivery. Vehicles will adapt in real-time, optimizing operations seamlessly.

Real-time data analysis will pave The way towards increased efficiency. Autonomous systems will incorporate strategies that recognize driving patterns. A comprehensive understanding of fuel requirements directly correlates with efficiency gains.

Additionally, The integration of fuel management technologies will align with mobility trends. As manufacturers innovate, widespread acceptance becomes increasingly likely. Emphasizing advanced fuel injection systems ensures sustainable solutions in The automotive industry.

- 🔧 Optimized fuel delivery

- 🌍 Enhanced emissions control

- ⚙️ Advanced diagnostics capabilities

- 🚗 Improved acceleration responsiveness

- ♻️ Reduced carbon deposits

- 📉 Lower fuel consumption rates

- 🔍 Greater reliability & maintenance

Real-Life Application of Fuel Injection Systems

Personal Experience with Fuel Injection Systems

Recently, I encountered a scenario where fuel injection systems demonstrated significant advantages. A friend’s vehicle experienced performance issues due To clogged fuel injectors. Through thorough inspections, we were able To identify The root cause promptly.

A thorough cleaning job restored function, showcasing these systems’ resiliency. Observing The instant difference in performance confirmed my understanding. Fuel injection systems enhance engine operation effectively.

Reflecting on this experience reinforces my appreciation for these technologies. Fuel injection systems shape modern automotive functionality in remarkable ways. Consistent improvements ensure that they will remain integral components of engineering.

Understanding Fuel Injection Systems

Fuel injection refers To processes involved in delivering fuel into an engine’s combustion chamber. This system differs significantly from traditional carburetors, which were widely used in older vehicles. Understanding fuel injection becomes crucial for improving vehicle efficiency. Insights into how these systems function enable drivers & mechanics alike To troubleshoot effectively.

Modern fuel injection systems offer precise control over fuel delivery. They allow for better fuel economy & reduced emissions. As vehicles have evolved, advanced technologies have emerged, enhancing performance & reliability. With advancements in electronics, these systems have taken vehicle efficiency To new heights.

For detailed insights on fuel injection systems, visit How Stuff Works. This resource provides a thorough overview of various fuel injection methods utilized in today’s vehicles. Understanding these methods aids in recognizing their advantages, ensuring proper maintenance & repair practices.

The technology behind fuel injection systems can vary significantly between manufacturers. Several types exist, including multi-port fuel injection & direct fuel injection. Each configuration possesses unique benefits affecting engine performance, emissions, & fuel economy. Familiarity with these distinctions proves beneficial when considering upgrades or repairs.

For a deeper cleaning solution recommendation, check out Snap-on EEFI Cleaner. Regular maintenance enhances performance & longevity. Utilizing specialized cleaners helps in maintaining fuel injector efficiency, promoting smooth engine operation.

Types of Fuel Injection Systems

Multi-Port Fuel Injection

Multi-port fuel injection (MPFI) employs injectors situated near each intake valve. This method ensures uniform distribution of fuel, enhancing combustion efficiency. Consequently, MPFI systems help achieve better fuel economy & lower emissions compared To older systems. Vehicles equipped with MPFI often enjoy improved throttle response & overall performance.

MPFI systems operate using various sensors & electronic controls. These components monitor engine conditions, adjusting fuel delivery accordingly. Such meticulous management fosters optimal combustion, leading To efficient energy use. Owners can appreciate these systems’ benefits through direct observations of performance enhancements.

Specialized tools are necessary for diagnosing issues in MPFI systems. Maintaining proper fuel pressure & injector cleanliness ensures longevity & performance. Owners must understand these factors To ensure optimal operation & troubleshooting efficiency.

Direct Fuel Injection

Direct fuel injection (DFI) represents a more advanced fuel delivery strategy. In this configuration, fuel injectors deliver fuel directly into The combustion chamber under high pressure. This approach allows for more precise control over when & how much fuel enters The chamber, optimizing combustion efficiency.

Fuel efficiency greatly improves with direct injection systems. Vehicles can achieve higher thermal efficiency, translating into better performance. Furthermore, DFI technology reduces particulate emissions, making vehicles less harmful To The environment. Understanding these developments enhances appreciation for today’s advanced automotive technologies.

DFI systems require specialized maintenance compared To traditional methods. Regular cleaning of fuel injectors becomes critical for maintaining efficiency. Familiarity with recommended maintenance practices is essential for ensuring The durability & performance of these advanced systems.

Benefits of Fuel Injection Systems

Improved Fuel Efficiency

Enhanced fuel efficiency remains one of fuel injection systems’ primary advantages. Accurate fuel delivery means engines consume less fuel while producing The same power. This efficiency translates into significant savings over time, making these systems an attractive option for vehicle owners.

Drivers interested in maximizing their fuel efficiency can access various aftermarket options, including tuning chips & performance chips. These devices optimize fuel mapping within The engine control unit. As a result, car owners experience improved mileage without sacrificing performance.

Another key aspect contributing To fuel efficiency relates To vehicle weight. By using lighter materials, manufacturers can also contribute positively. This synergy between weight reduction & efficient fuel delivery systems helps achieve impressive fuel economy figures.

Reduced Emissions

Modern fuel injection systems contribute significantly To reduced vehicle emissions. Combustion efficiency plays a crucial role, resulting in better performance of catalytic converters. Cleaner combustion means fewer harmful pollutants enter our atmosphere, making today’s vehicles more environmentally friendly.

Regulations surrounding emissions continue To evolve, pushing manufacturers toward cleaner technologies. Fuel injection systems inherently adapt To these requirements through precise fuel delivery. Resultantly, vehicle owners can drive newer models, confident in knowing their cars comply with emission standards.

Keeping fuel injectors clean serves as a critical part of maintaining low emissions. Regular maintenance ensures optimal performance, allowing engines run cleaner. As such, vehicle efficiency & environmental stewardship go hand-in-hand.

Common Issues with Fuel Injection Systems

Clogged Injectors

Fuel injectors can experience clogging due To dirt or debris. Such blockages prevent proper fuel delivery, which compromises engine performance. Symptoms of clogged injectors include rough idling, decreased power, & increased fuel consumption. Addressing these issues promptly can restore optimal operation.

Regular cleaning of fuel injectors helps prevent clogging. Various products exist on The market that can assist in this process. By performing routine maintenance, vehicle owners can help their cars avoid performance losses associated with clogged injectors.

Diagnosing clogged injectors often requires specialized equipment. This equipment measures fuel flow rates & indicates injector performance. Gaining familiarity with these tools enhances one’s ability To identify issues early, preventing costly repairs down The line.

Electrical Failures

Electrical issues can also affect fuel injection systems. Sensors & wiring play critical roles in system performance. Failures in these components may lead To improper fuel delivery & erratic engine behavior. Identifying electrical failures quickly ensures timely repairs & prevents further complications.

Modern vehicles utilize advanced electronic controls in their fuel injection systems. Learning about these controls enhances understanding of common issues. Armed with this knowledge, vehicle owners can navigate repairs more confidently & efficiently.

Regular inspections of electrical components can help prevent failures. Mechanics typically check wiring, connectors, & sensors during routine maintenance. Staying proactive ensures reliability & longevity of fuel injection systems in modern vehicles.

Maintenance Practices for Fuel Injection Systems

Regular Cleaning

Conducting regular cleaning of fuel injection systems remains paramount. Dirt & impurities can build up, leading To performance issues. By investing time in cleaning procedures, vehicle owners can maximize their car’s efficiency & reliability. This simple maintenance task pays dividends over time.

Cleaning can be an easy process with proper tools. Various fuel injector cleaning kits exist, offering everything needed for thorough maintenance. Following manufacturer guidelines ensures safety & efficiency during cleaning procedures.

Regularly scheduled cleaning helps prevent significant performance declines. Scheduling cleaning sessions based on mileage can serve as a guideline. Establishing a routine protects investments & fosters long-lasting vehicle performance.

Inspection of Components

Routine inspections of key components within fuel injection systems contribute significantly. Identifying wear & tear early can prevent costly repairs later. Mechanics typically inspect fuel pumps, filters, & injectors themselves as part of standard maintenance practices. Catching issues early forms an essential part of vehicle ownership.

Visual inspections can reveal abnormal leakage or damage. Recognizing these warning signs indicates when component replacements or repairs may be due. Staying aware of changes in performance can help inform maintenance schedules, ensuring peak efficiency.

Utilizing preventive diagnostics tools can enhance inspection processes. Various devices offer quick assessments of system performance. Embracing technological advancements in diagnostics leads To improved maintenance practices.

Fuel Injection System Comparison

| System Type 🚗 | Efficiency ⚡ | Cost 💰 | Maintenance Needs 🧰 | Emissions 🌍 |

|---|---|---|---|---|

| Multi-Port Fuel Injection | High | Moderate | Regular | Low |

| Direct Fuel Injection | Very High | High | High | Very Low |

| Throttle Body Injection | Moderate | Low | Low | Moderate |

Technology Behind Fuel Injectors

Advanced Sensors

Advanced sensors contribute immensely within fuel injection systems. These components monitor various parameters, including oxygen levels & fuel pressure. Feedback from these sensors allows engine control units To adjust fuel delivery accordingly. This ensures optimal performance & efficiency.

Various sensor types serve specific purposes within systems. Oxygen sensors evaluate exhaust gases, guiding adjustments for optimal combustion. Understanding sensor functionality provides insights into overall system performance, highlighting areas for improvement.

Learning about advanced sensors requires staying informed about trends. Automotive technology evolves continuously, making it necessary for owners & mechanics alike To stay updated. Embracing ongoing education helps ensure proper understanding & optimal maintenance for fuel injection systems.

Engine Control Unit (ECU)

Engine control units function as brain of modern fuel injection systems. This technology executes critical adjustments based on sensor feedback. Proper calibration of an ECU enhances responsiveness & efficiency, ensuring smooth operation. Understanding ECS technologies remains vital for achieving optimal vehicle performance.

Considerations regarding ECU upgrades often arise among performance enthusiasts. Tuning options & performance chips can significantly enhance engine behavior. A deep understanding of ECU functionalities aids drivers in exploring enhancements that improve efficiency.

Bluetooth technology has led To numerous diagnostic innovations. Mechanics can utilize ECU-based scanning tools for quick assessments. These tools provide access To performance data, enabling more effective troubleshooting & repairs.

Learning Experience

While working on fuel injection systems, I gained valuable insights. Experiences helped deepen my appreciation for vehicle efficiency. Observing how precise adjustments alter performance showcased technology’s incredible advancements in modern vehicles.

What is an engine fuel injection system?

An engine fuel injection system is a crucial component that delivers The precise amount of fuel into The engine’s combustion chamber. It replaces The older carburetor system & provides better fuel efficiency, reduced emissions, & improved overall performance.

How does fuel injection work?

Fuel injection works by using electronically controlled injectors To spray fuel directly into The engine’s intake manifold or combustion chamber. Sensors monitor various engine parameters, & The engine control unit (ECU) adjusts The fuel delivery for optimal performance.

What are The different types of fuel injection systems?

There are several types of fuel injection systems, including port fuel injection (PFI), direct fuel injection (DFI), & sequential fuel injection. Each type has its benefits & drawbacks, depending on The engine design & application.

What are The advantages of fuel injection over carburetors?

Fuel injection offers several advantages over carburetors, including improved fuel efficiency, better throttle response, lower emissions, & more precise fuel delivery under varying conditions. Additionally, fuel injection provides enhanced performance in cold starts.

What role does The engine control unit (ECU) play in fuel injection?

The engine control unit (ECU) is responsible for managing The fuel injection system by processing data from various sensors. It calculates The ideal fuel-To-air ratio & controls The timing & amount of fuel injected into The engine To ensure optimal performance & emissions.

How can I tell if my fuel injection system is malfunctioning?

Signs of a malfunctioning fuel injection system can include poor acceleration, reduced fuel efficiency, rough idling, engine misfires, or The check engine light illuminating. If you experience these symptoms, it’s advisable To have The system checked by a professional.

What maintenance is required for a fuel injection system?

Regular maintenance for a fuel injection system includes keeping The fuel filters clean, using high-quality fuel, & occasionally cleaning The fuel injectors. It’s also important To monitor engine performance & address any issues promptly.

Can I upgrade my fuel injection system?

Upgrading your fuel injection system is possible, & many performance-oriented parts are available To enhance fuel delivery & engine performance. However Understanding the Engine Fuel Injection System, it’s important To consult with an expert To ensure compatibility with your engine & vehicle.

What are fuel injectors made of?

Fuel injectors are typically made from durable materials such as stainless steel, plastic, or composite materials designed To withstand The high pressures & temperatures within an engine. This ensures reliability & longevity in fuel delivery.

What is The average lifespan of fuel injectors?

The lifespan of fuel injectors can vary widely depending on driving conditions, fuel quality, & maintenance practices. Generally, they can last anywhere from 50,000 To over 100,000 miles before needing replacement.

Do fuel injectors need To be cleaned?

Yes, fuel injectors can become clogged over time due To deposits from fuel & additives. Regular cleaning can prevent performance issues. Fuel injector cleaning services are available, or fuel system cleaners can be added To The fuel tank.

Conclusion

In summary, understanding your engine’s fuel injection system is key To keeping your vehicle running smoothly & efficiently. By grasping how this system works & ensuring it’s well-maintained, you can improve fuel economy & reduce emissions, saving you money in The long run. Regular check-ups & timely repairs can make a big difference. So, whether you’re a car enthusiast or just want To save on gas, taking The time To learn about fuel injection pays off. A little knowledge goes a long way in boosting your vehicle’s performance & longevity—so stay informed & drive smart!